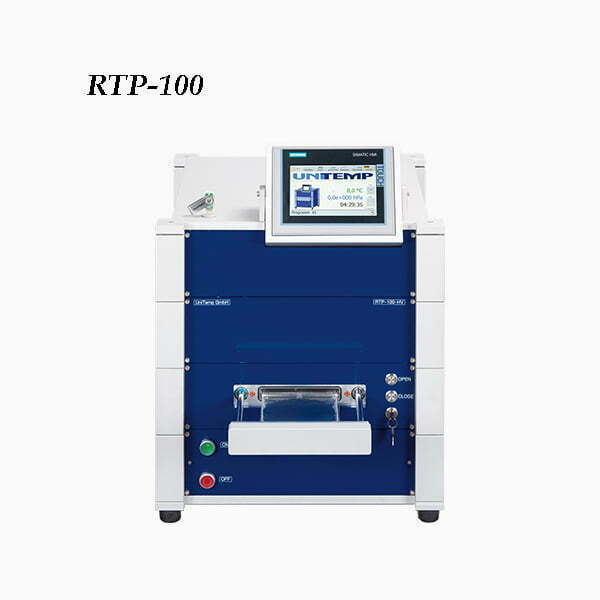

Plasma Temperature Process Oven RTP-300

- Brand:德國UNITEMP

- Fast ramp up heating of substrates and wafers parallel with plasma cleaning, Special surface treatment for wafers or substrates, Fluxless soldering, Flip chip process, Adhesive bonding, Solder bump reflow, Soldering of power devices, Prototype development

- A major advantage is

that low pressure plasma can readily penetrate crevices. Even intricately shaped parts can be

easily cleaned or etched in a plasma, because the gas can penetrate hollow spaces which

can not be reached by liquids.

- Key features are precise controlled fast ramp-up and ramp-down rates.

- The heating is done by

Infrared lamps with one heating zone at the chamber base.

- The vacuum coupling on the backside allows the connection of a vacuum pump system.

- Two gas lines with Mass Flow Controllers and magnetic valve are default.